OEM & Custom ( Single piece customization)

CNC machining service in China For 10+ Years

- Competitive price with good quality

- Small order is acceptable

- Short delivery time (7-25days according to order Qty)

- Customized size and specification /OEM available

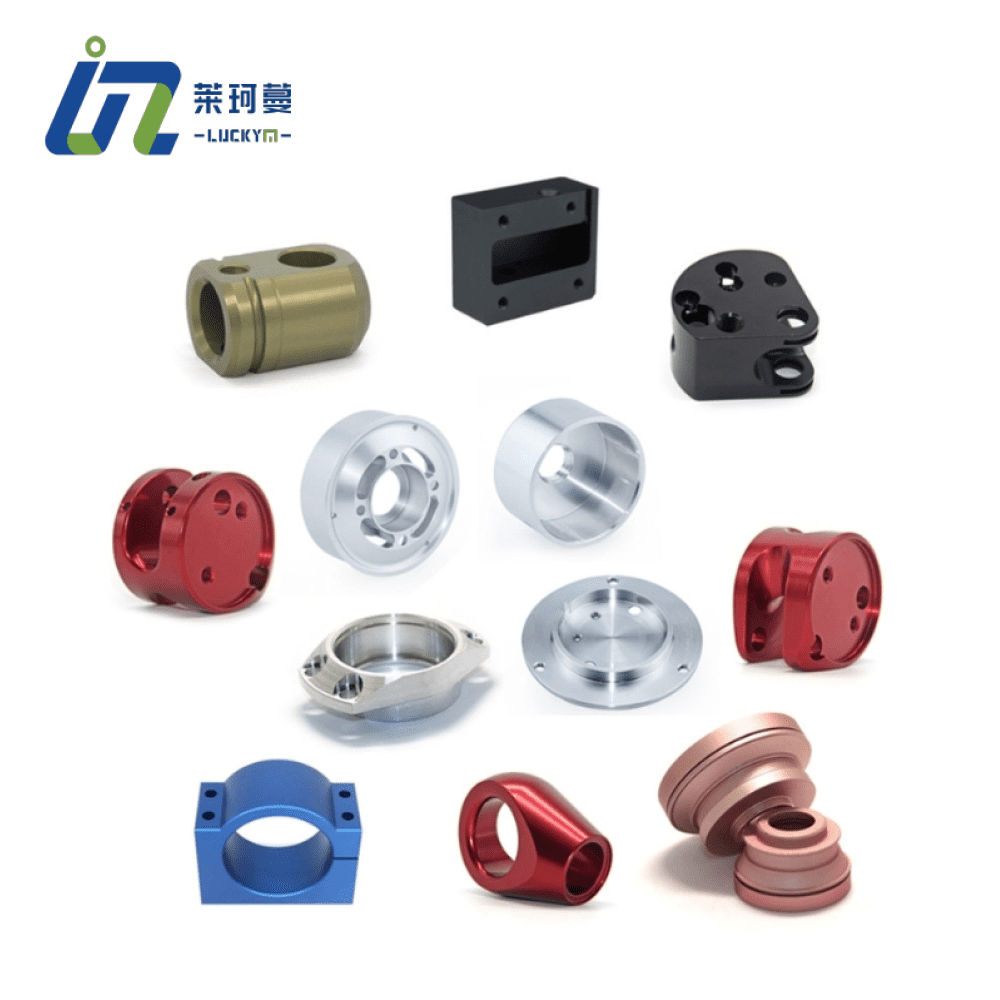

Our Popular CNC machined parts

Precision Medical Components

- Material: Aluminum, Stainless Steel, Brass, Steel, Iron, Bronze, Titanium, copper, Magnesium, Plastic

- Color: Blank, Red, Support Customize

- Style: Customized

- Application: Medical

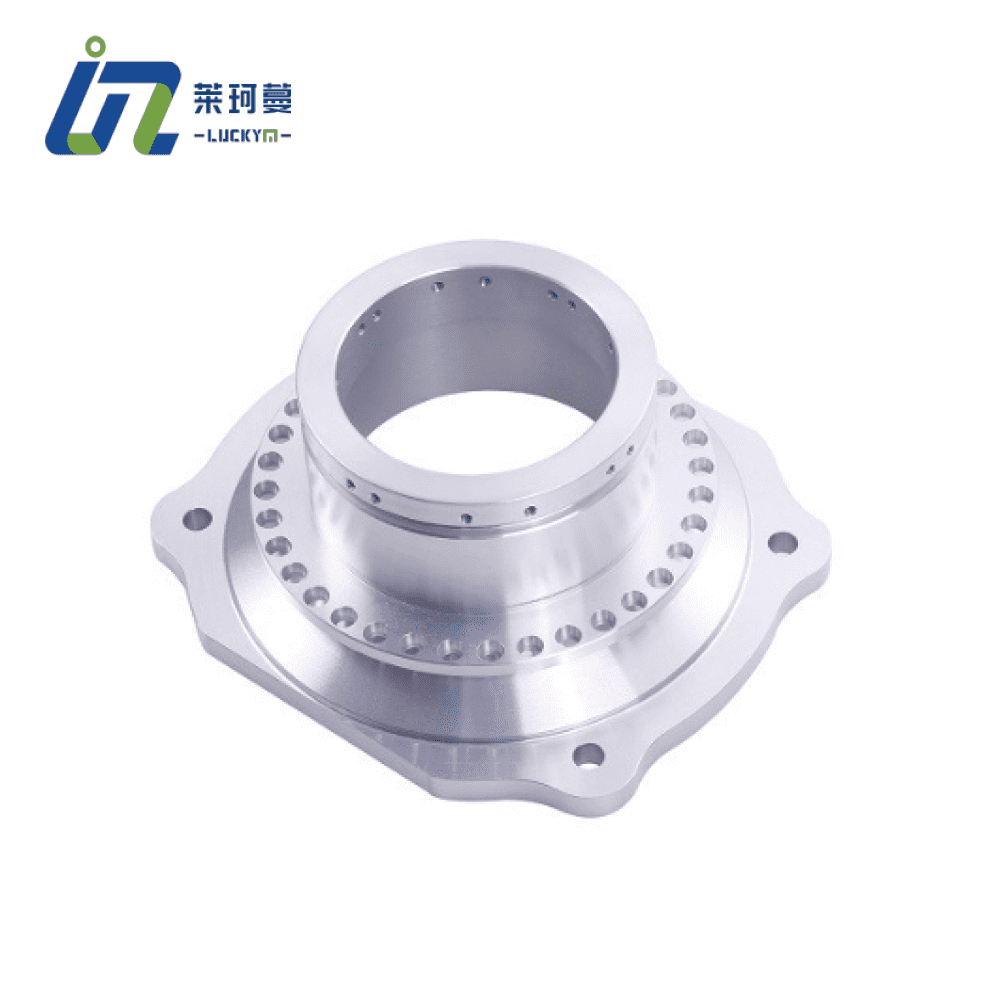

Custom Aerospace Parts

- Material: Aluminum, Stainless Steel, Brass, Steel, Iron, Bronze, Titanium, copper, Magnesium, Plastic

- Color: black/white/red / Sliver / yellow in general

- Style: Customized

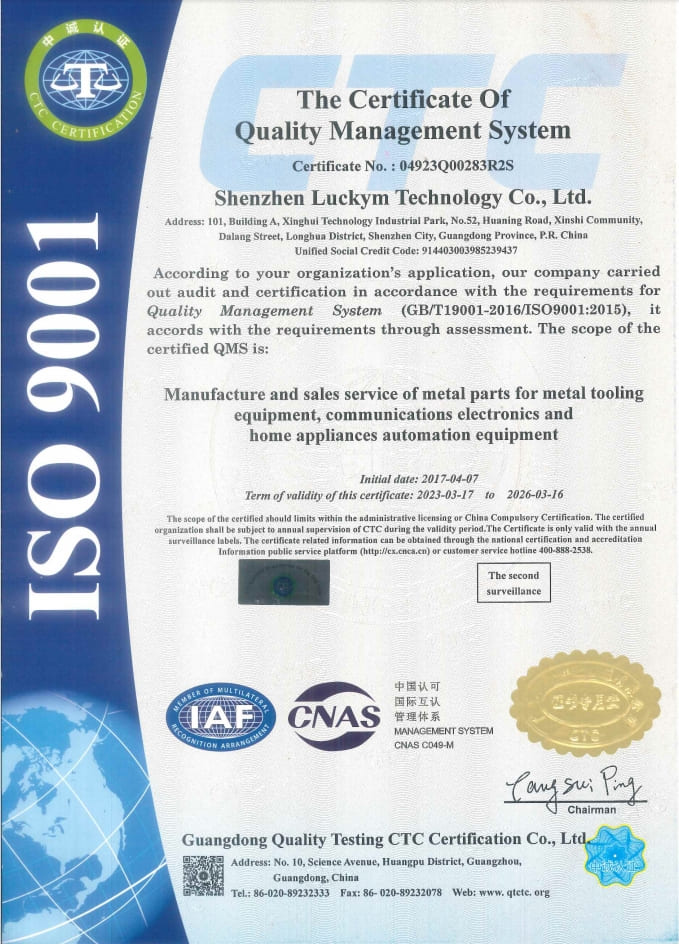

- Certification: ISO9001

- Application: Aerospace

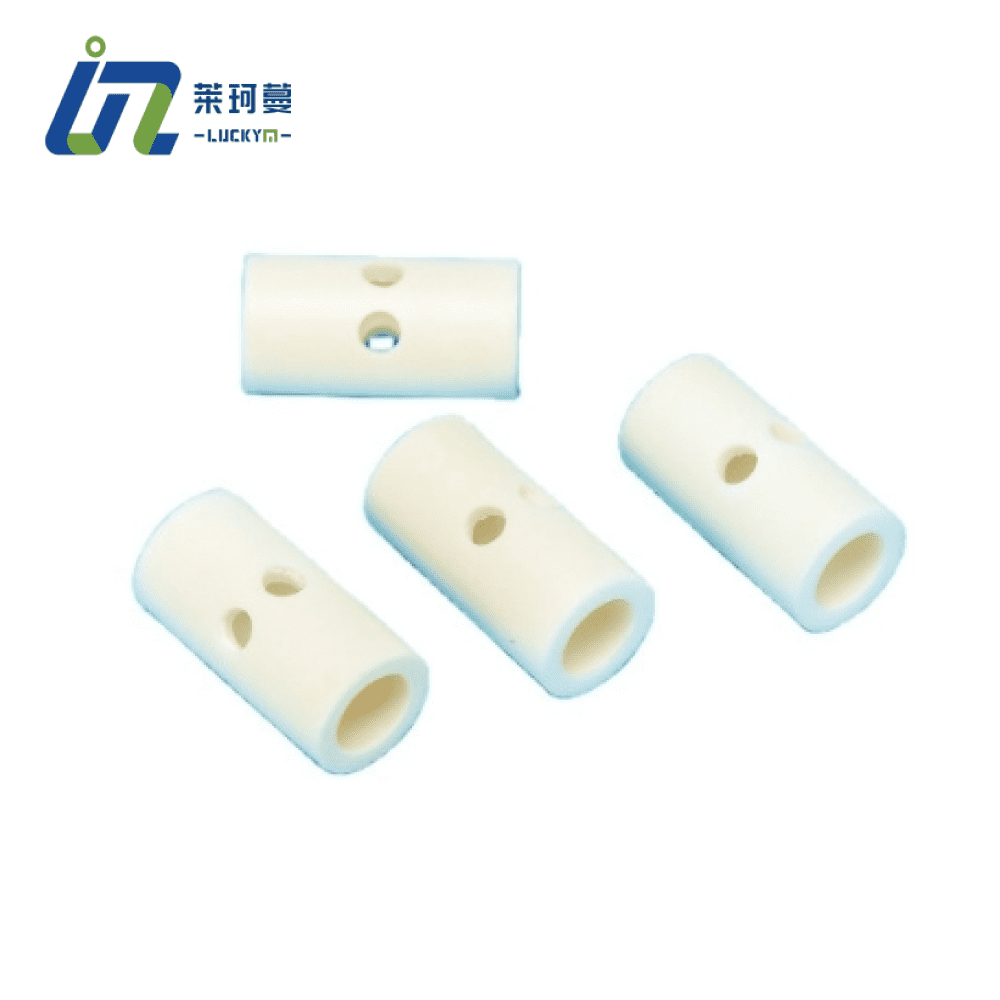

Precision Ceramic Parts

- Optional Materials: alumina, zirconia, silicon carbide, silicon nitride, steatite optional

- Outer diameter:0.5 ~800 mm

- Length:1~1000mm

- Tolerance: +/-0.002mm

- Surface treatment: Polished, Glazed, Metalized availability

- Style: Customized

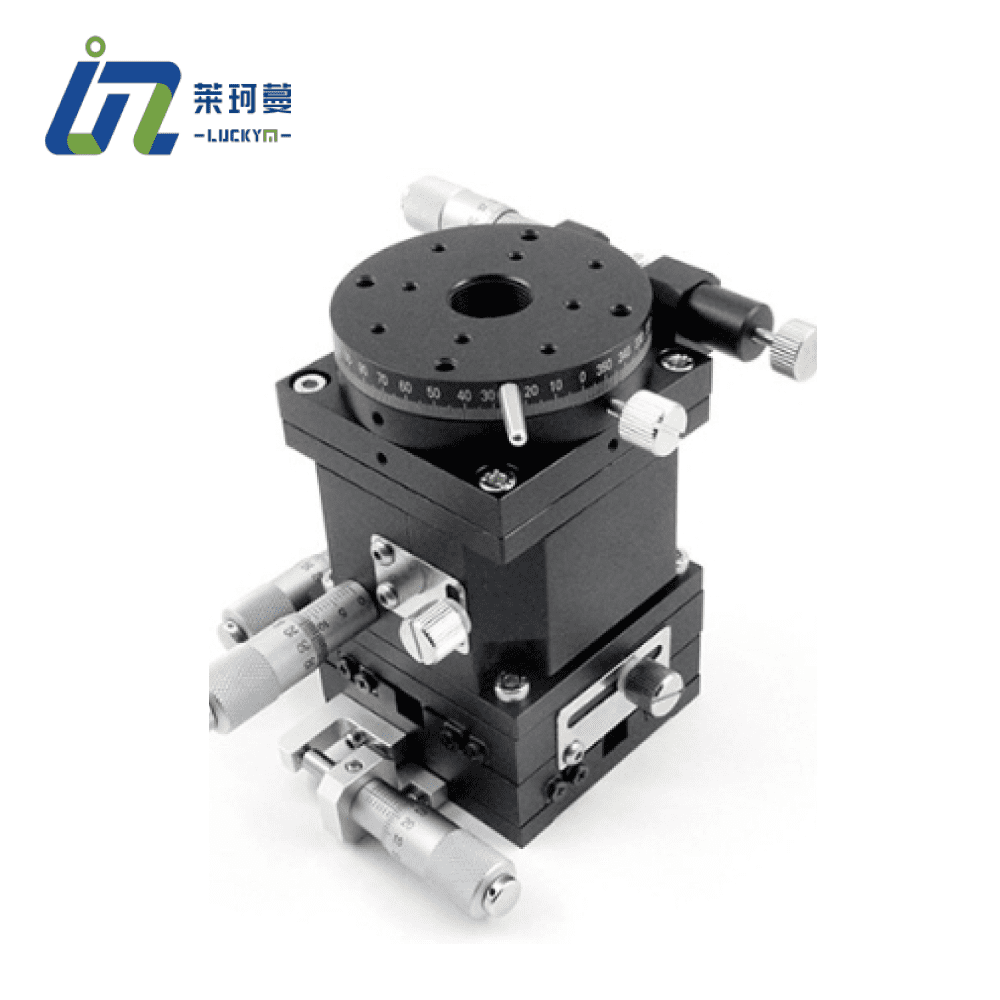

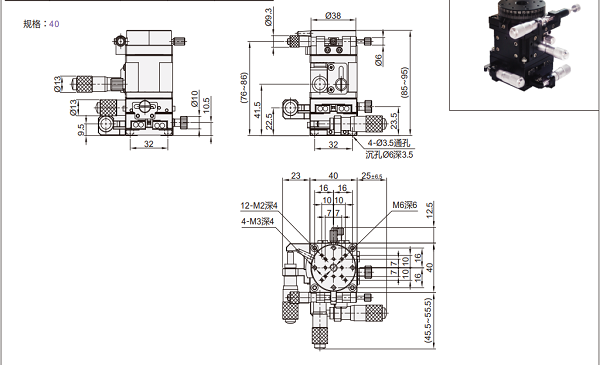

XYZ Linear Stage

- Model Number: LMG01AXYZθ

- Material: Aluminum, Stainless Steel

- Standard: DIN, ASTM, GB, JIS, ANSI, BS

- The direction of movement: XYZ θ Axis

- Size: 60*60MM

- Weight: 2kg

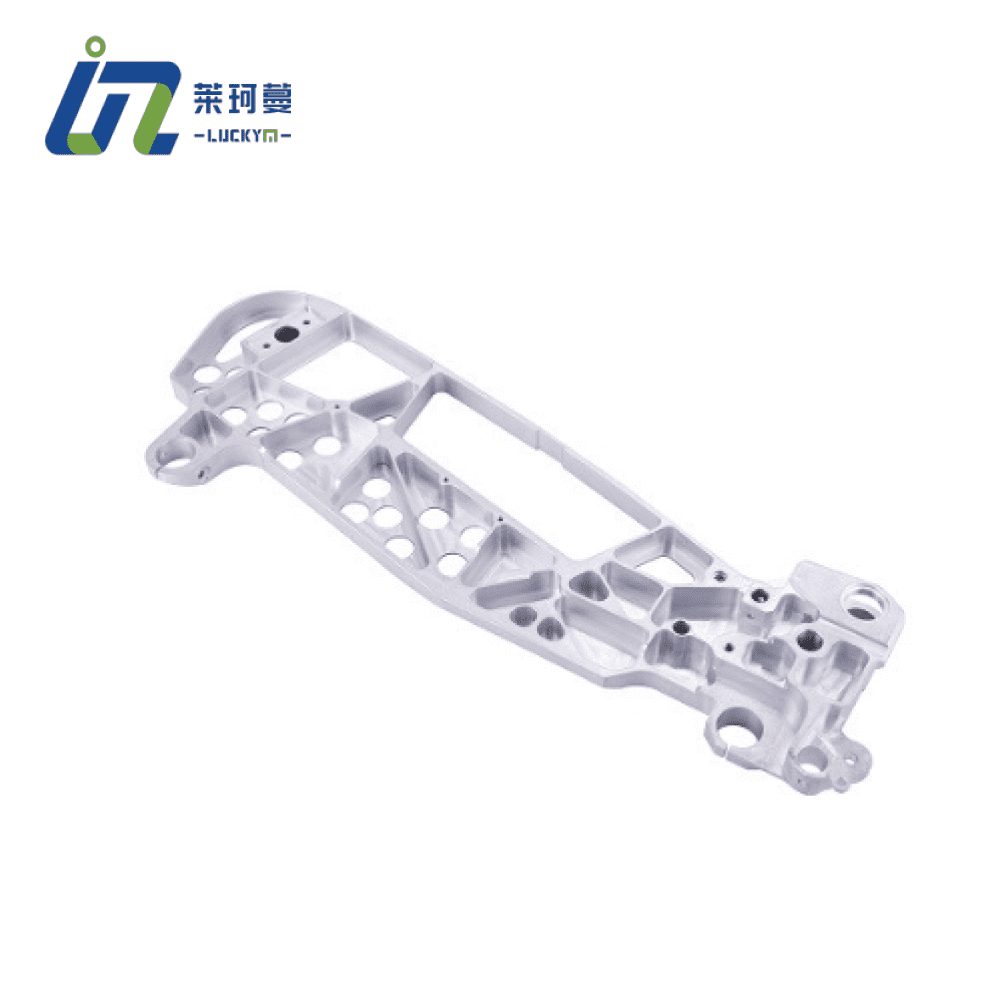

CNC Machined Aerospace Parts

- Material: Aluminum Alloy Stainless Steel

- Surface Treatment: Polishing

- Application: Aeronautics And Astronautics

- Machining Method: CNC Milling

- Certification: ISO9001

CNC Machined Parts with CMM Inspection

- Inspection: CMM, 3D Scanner, Etc.

- Shape: Customized

- Process: CNC Machining

- Surface Finish: Anodizing, Plating, Polishing, Etc.

- Tolerance: ±0.001mm

CNC Machining Plastic Parts

- Material: ABS, AS, PA, PE, PP, PVC, PC, PE, Nylon, EPDM, POM, EPT,etc

- Color: White ,Blank ,Red , Support Customize

- Style: Customized

- Surface Treat: Paint, texture

- Temperature: -40°C to+300°C

Milling Turning Machine Parts

- Material: Aluminum, Stainless Steel, Brass, Steel, Iron, Bronze, Titanium, copper, Magnesium, Plastic

- Color: Clear Anodize

- Style: Customized

- Machining: CNC Machining

Our CNC Machining Service Capabilities

Shenzhen Luckym Technology Co., Ltd was founded in 2014, the company specializes in precision parts processing, non-standard parts custom processing, die casting, injection molding, stamping, sheet metal and tooling, fixture, customization, and assembly services. We focus on client’s demands and client’s satisfaction

CNC Machining Service

CNC Turning Service

CNC Milling Service

Die Casting Service

Sheet Metal Fabrication

Injection Molding Service

Our standard PO procurement process flow

Prototyping —-> FA approval —-> Quality Control Plan —> Manufacturing Process Instruction —> Batch Production —> Inspection —> Shipping

Custom Your Products

Customized high-quality parts Demand, More than 10 years of factory experience, instant online quotes in minutes, samples as fast as 7 days, and Orders in 15 days.

- Step 1: Upload Your CAD Files

Upload your file through the quote page or email your project messages to us. All files are under NDA supports.

- Step 2: Quote & DFM Analysis

We will send back the read-time quote together with design for manufacture analysis within 24 hours

- Step 3

Once you agree with the quote and manufacturing proposal, we will start to run the production with your final CAD design.

- Step 4: Get Your Parts

Prototypes and parts will be produced within a few days and delivered directly to you by international express.

Our Certificates

Quality inspection equipment

Liability System and Technician self-inspection, Periodical QC online per hour, Final inspection 100% from each lot, standard inspection report

Semi-automatic CMM

Handheld film thickness gauge

Hite-400

Hexagon automatic2.5 dimensional test

Hite-600

Material hardness tester

Why choose us: Custom CNC Machining Services

- Pro Service Team Our professional service team are ready to answer any question from customers 24/7/365

- Expert Engineers The founder and the engineers have at least 10 years experience in rapid manufacturing industry

- Top Quality Guarantee All our parts have been fully inspected before shipment. Quality is our life.

- Powerful Production Ability LuckyM invests a series of precise machines to meet your any volume production needs. Always a timely report.

Customer Satisfaction Exhibition Site

For over 10 years, Luckymfc has been an established ISO9001, ISO13485, and AS9100D-certified manufacturer of high-precision CNC machined components and customized automation equipment. We focus on these two areas as they typically work hand in hand with our ethos of achieving precision and efficiency.

Our boss, Sam Zhang, started as an apprenticed machinist out of college. After working in the industry for five years, he decided to start his shop due to his knack for efficient machining, stamping, and die-casting practices.

We have gone from a small shop to a shop spanning two locations with over 80 CNC machines, lathes, and several in-house processes, such as laser engraving. Our location puts us in a stone’s throw away from high-quality vendors offering a wide range of finishing finishing processes.

To back up our quality, we have 3 CMMs and put a HUGE emphasis on the quality of our products and services.

So if you are interested in working with a highly qualified machining, stamping, and die-casting supplier, check us out!

Frequently Asked Questions

Yes, the sample fee depends on the product geometry, and the fee will be returned to your bulk order

Depends on your part geometry, normally within 3-7 days

Sample 3-7days; Mass production order 7-45 days depending on quantity and part complexity

Prototyping —-> FA approval —-> Quality Control Plan —> Manufacturing Process Instruction —> Batch Production —> Inspection —> Shipping

Please send your sample to our factory, and then we can copy or provide you with better solutions. Please send us pictures or drafts with dimensions (Length, Height, Width), CAD or 3D file will be made for you if place orders

Yes, we can sign the NDA before getting your drawing and will not release it to the third party without your permission

Of course! Customer-first is our company philosophy. You need to tell us the delivery time when placing the order, and we will do our best to adjust the production schedule.

We can provide shot blasting, polishing, painting, powder coating, anodizing, electroplating, Chrome Plating(Matt/Bright), Nickle plating, Zinc Plating, mirror polishing, trivalent chromate passivation,e-coating, etc.

We regularly quote within 12 hours after we get your inquiry. If it is very urgent, please call us or tell us in your email so that we will proceed with your inquiry as a priority.

We always support custom-made demands as per different materials, dimensions, and designs.

We will make 100% inspection before packing and delivery and make sure the products 100% meet your requirements. If there are any problems during using, please tell us anytime, we will reply you in time

Yes, we could offer different discounts according to your order quantity.

You can choose any mode of transportation you need, sea delivery, air delivery or express delivery.

50% with order, 50%before shipment

Normally we pack the molds with a vacuum bag and a wooden box.

The annual quantity, materials selected, application or function of the parts, project delivery schedule, net weight(if you don’t have it, you must give us the 3D file), and destination port.

See What Customer Saying Concern Our Company

Hear directly from our partners about the real-world impact of our CNC Machining Service. Their experiences spotlight the reliability and quality we bring to every collaboration.

Partner With The Right Factory

Kindly share with us about your idea of your CNC machining parts. Let’s make good things happen togeher!

1/F, Building A , No.52 Huaning Road, Longhua District,Shenzhen, China

Phone : +86 19917152469

Website: www.luckymfc.com

Sunny +86 19917152469

Get Sample Now !

Don’t hesitate, trust us with your project. We offer a full refund if there’s any issue with our product.